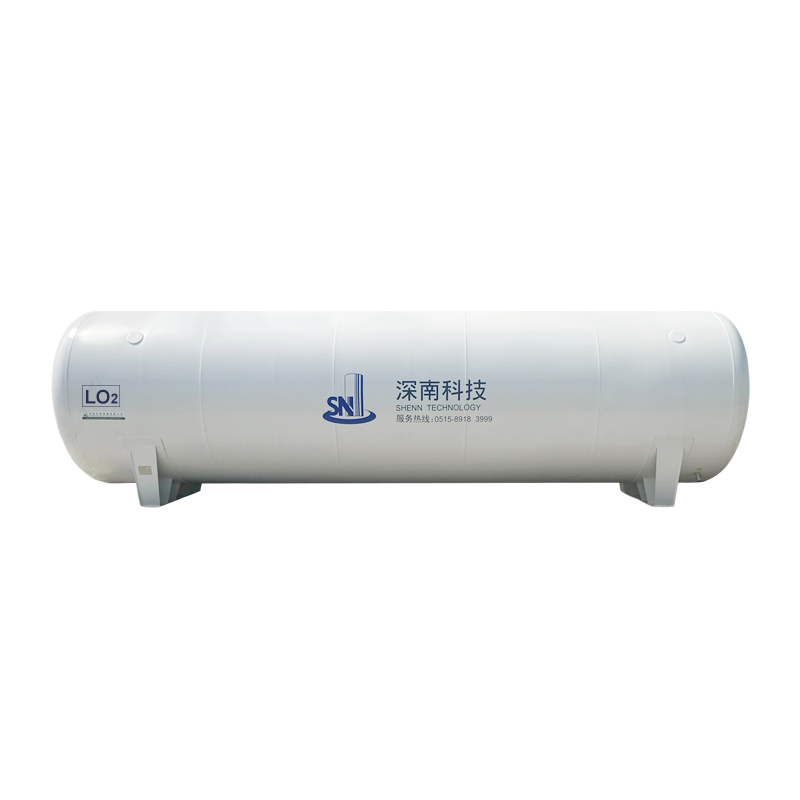

I-HT (Q) LO₂ ITanki yokuGcina - Izisombululo eziSebenzayo nezithembekileyo zokuGcina

Iinzuzo zeMveliso

● Iimpawu ezigqwesileyo zokugquma i-thermal:Iimveliso zethu zineempawu ezibalaseleyo zokugquma i-thermal, ezithintela ngokufanelekileyo ukuhanjiswa kobushushu kunye nokuqinisekisa ukulawulwa kweqondo lokushisa.

● Inkqubo yokuvula ivacuum:Itekhnoloji yethu ye-vacuum yokusika iqinisekisa ukuba imveliso ayinayo nayiphi na umoya okanye umswakama, iphucula ukusebenza kwayo yonke kunye nokuqina.

● INkqubo yeMibhobho eNgafezekanga:Siye sayila inkqubo yokubhobhoza egqibeleleyo ukuze siqinisekise ukuhamba kakuhle nokungenamthungo kolwelo, sicutha nakuphi na ukuphazamiseka okanye ukuvuza. Baqolileyo

● I-anti-corrosion coating:Iimveliso zethu zisebenzisa i-anti-corrosion coating ekhulileyo nethembekileyo, ebonelela ngokhuseleko oluthembekileyo lokuchasa umhlwa kunye nokwandisa ubomi bayo benkonzo. Iphuculwe

● Iimpawu zoKhuseleko:Ukongeza kwezi mpawu zingentla, iimveliso zethu zikwanazo iimpawu zokhuseleko ezomeleziweyo ezifana nolwakhiwo olomeleleyo kunye nezixhobo ezikhuselekileyo zokuqinisekisa ukhuseleko lwabasebenzisi.

Iimbonakalo

● Imilinganiselo yoKhuseleko eyomeleziweyo:Iimveliso zethu zixhotyiswe ngeempawu zokhuseleko eziphezulu ezifana nezitshixo zebhayometriki, ukuhanjiswa kwedatha efihliweyo kunye nesakhono sokubeka iliso kude. La manyathelo aqinisekisa ukhuseleko oluphezulu ekufikeleleni okungagunyaziswanga kunye noxolo lwengqondo kubasebenzisi.

● Amava omsebenzisi aLula:Siye sayila iimveliso zethu sicinga ngokusebenziseka lula. Ukusuka kunxibelelwano olubonakalayo kunye nolawulo olusebenziseka lula ukuya kwiinkqubo ezizenzekelayo kunye neenketho zokuseta ngokukhawuleza, ukusebenzisa iimveliso zethu kulula kwaye kulula.

● Nciphisa ilahleko kunye neNkunkuma:Iimveliso zethu zisebenzisa itekhnoloji ephambili ukunciphisa ilahleko kunye nenkcitho. Nokuba kungokusebenzisa amandla afanelekileyo, ukusetyenziswa kwezinto eziphuculweyo okanye iinkqubo zokubeka iliso ezikumgangatho ophezulu, iimveliso zethu zinceda ukunciphisa inkcitho yobutyebi kunye nokwandisa isivuno.

● Ugcino Olulula:Siyaqonda ukuba kubaluleke kangakanani ukugcinwa lula kubathengi bethu. Iimveliso zethu zibonisa uyilo lwemodyuli kunye nezinto ezisuswayo ukuze kube lula ukulungisa iingxaki kunye nokulungiswa. Ukongezelela, sinikezela ngezikhokelo zokugcinwa okupheleleyo kunye nokubonelela ngoncedo lwangexesha ukuqinisekisa ukusebenza kakuhle kunye nokunciphisa ixesha lokuphumla.

Isicelo seMveliso

● Ishishini lezonyango:Iimveliso zethu zidlala indima ebalulekileyo ekugcinweni kweegesi ezinyibilikisiweyo ezisetyenziswa kwizicelo zonyango ezinje ngogcino lwe-cryogenic lwezitofu zokugonya, iimveliso zegazi kunye nezinye izixhobo zonyango ezibuthathaka. Iqinisekisa ukugcinwa okukhuselekileyo kwezi zixhobo ezibalulekileyo, ukugcina amandla kunye nomgangatho wazo.

● Ishishini loomatshini:Amashishini amaninzi axhomekeke kwirhasi enyibilikisiweyo kumandla nakumatshini opholileyo. Iimveliso zethu zibonelela ngezisombululo ezikhuselekileyo zokugcinwa kwezi gesi, ziqinisekisa ukusebenza okungaphazamisekiyo ngelixa zihambelana nemigangatho ephezulu yokhuseleko.

● Ishishini lemichiza:Iirhasi ezinyibilikisiweyo zisetyenziswa ngokubanzi kwiinkqubo ezahlukeneyo zeekhemikhali ezifana nefriji kunye nokufudumeza, kunye nezixhobo zokuvelisa. Iimveliso zethu zibonelela ngemekobume ethembekileyo nelawulwayo yokugcina ezi gesi, ukuthintela ukuvuza kunye nokunciphisa iingozi ezinokwenzeka.

● Ishishini lokutya:Irhasi enyibilikisiweyo isetyenziselwa ukukhenkceza, ukugcinwa ngokutsha, icarbonation kunye nezinye iinkqubo kushishino lokutya. Iimveliso zethu ziqinisekisa ukugcinwa okukhuselekileyo kwezi gesi, zigcina ubunyulu bazo kunye nokuthintela ukungcoliseka, ngaloo ndlela zigcina umgangatho kunye nokutsha kokutya.

● Ishishini le-Aerospace:Kwimizi-mveliso ye-aerospace, iigesi eziyilwelwe zisetyenziselwa ukuqhubela phambili, ukucinezela, nokulawula ubushushu beerokhethi, iisathelayithi neenqwelo-moya. Iimveliso zethu zibonelela ngezisombululo ezikhuselekileyo nezisebenzayo zokugcina ezi gesi ziguquguqukayo, ziqinisekisa ukhuseleko oluphezulu ngexesha lokuthutha kunye nokusetyenziswa.

Ngokubanzi, iimveliso zethu zizisombululo ezibalulekileyo zokugcina iigesi ezinamanzi kumashishini ahlukeneyo, ukuqinisekisa ukhuseleko, ukusebenza kakuhle kunye nomgangatho wemisebenzi yabo.

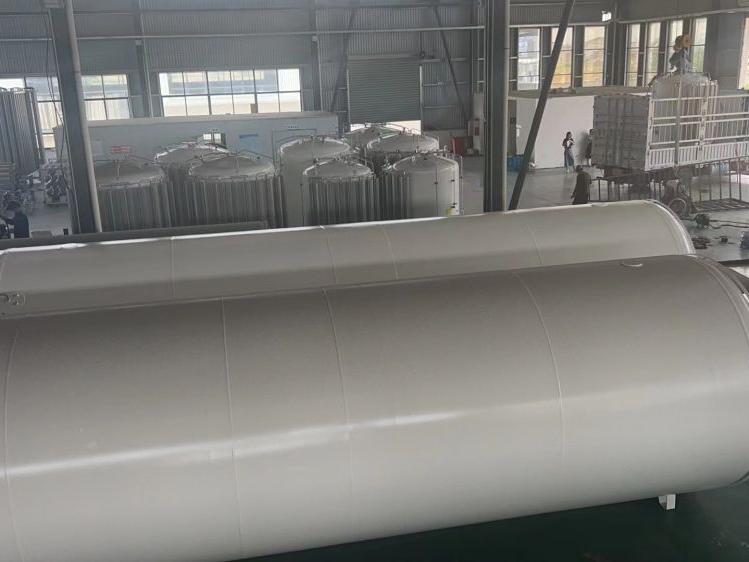

Umzi-mveliso

Indawo yokuTyeka

Indawo yokuvelisa

| Inkcazo | Umthamo osebenzayo | Uxinzelelo loyilo | Uxinzelelo lokusebenza | Ubuninzi boxinzelelo lokusebenza oluvumelekileyo | Ubuncinci boyilo lobushushu bentsimbi | Uhlobo lwenqanawa | Ubungakanani benqanawa | Ubunzima besitya | Uhlobo lokufakelwa kwe-thermal | Umyinge wokunyuka komphunga | Vacuum yokutywina | Ubomi benkonzo yoyilo | Uhlobo lwepeyinti |

| m³ | MPa | MPa | MPa | ℃ | / | mm | Kg | / | %/d(O₂) | Pa | Y | / | |

| HT(Q)10/10 | 10.0 | 1.000 | <1.0 | 1.087 | -196 | Ⅱ | φ2166*2450*6200 | (4640) | I-multi-layer winding | 0.220 | 0.02 | 30 | Jotun |

| HT(Q)10/16 | 10.0 | 1.600 | <1.6 | 1.695 | -196 | Ⅱ | φ2166*2450*6200 | (5250) | I-multi-layer winding | 0.220 | 0.02 | 30 | Jotun |

| I-HTC10 | 10.0 | 2.350 | <2.35 | 2.446 | -40 | Ⅱ | φ2166*2450*6200 | 6330 | I-multi-layer winding | ||||

| HT(Q)15/10 | 15.0 | 1.000 | <1.0 | 1.095 | -196 | Ⅱ | φ2166*2450*7450 | (5925) | I-multi-layer winding | 0.175 | 0.02 | 30 | Jotun |

| HT(Q)15/16 | 15.0 | 1.600 | <1.6 | 1.642 | -196 | Ⅱ | φ2166*2450*7450 | (6750) | I-multi-layer winding | 0.175 | 0.02 | 30 | Jotun |

| I-HTC15 | 10.0 | 2.350 | <2.35 | 2.424 | -40 | Ⅱ | φ2166*2450*7450 | (8100) | I-multi-layer winding | ||||

| HT(Q)20/10 | 20.0 | 1.000 | <1.0 | 1.047 | -196 | Ⅱ | φ2516*2800*7800 | (7125) | I-multi-layer winding | 0.153 | 0.02 | 30 | Jotun |

| HT(Q)20/16 | 20.0 | 1.600 | <1.6 | 1.636 | -196 | Ⅱ | φ2516*2800*7800 | (8200) | I-multi-layer winding | 0.153 | 0.02 | 30 | Jotun |

| HTC20 | 10.0 | 2.350 | <2.35 | 2.435 | -40 | Ⅲ | φ2516*2800*7800 | 9720 | I-multi-layer winding | ||||

| HT(Q)30/10 | 30.0 | 1.000 | <1.0 | 1.097 | -196 | Ⅱ | φ2516*2800*10800 | (9630) | I-multi-layer winding | 0.133 | 0.02 | 30 | Jotun |

| HT(Q)30/16 | 30.0 | 1.600 | <1.6 | 1.729 | -196 | Ⅲ | φ2516*2800*10800 | (10930) | I-multi-layer winding | 0.133 | 0.02 | 30 | Jotun |

| I-HTC30 | 10.0 | 2.350 | <2.35 | 2.412 | -40 | Ⅲ | φ2516*2800*10800 | 13150 | I-multi-layer winding | ||||

| HT(Q)40/10 | 40.0 | 1.000 | <1.0 | 1.099 | -196 | Ⅱ | φ3020*3300*10000 | (12100) | I-multi-layer winding | 0.115 | 0.02 | 30 | Jotun |

| HT(Q)40/16 | 40.0 | 1.600 | <1.6 | 1.713 | -196 | Ⅲ | φ3020*3300*10000 | (13710) | I-multi-layer winding | 0.115 | 0.02 | 30 | Jotun |

| HT(Q)50/10 | 50.0 | 1.000 | <1.0 | 1.019 | -196 | Ⅱ | φ3020*3300*12025 | (15730) | I-multi-layer winding | 0.100 | 0.03 | 30 | Jotun |

| HT(Q)50/16 | 50.0 | 1.600 | <1.6 | 1.643 | -196 | Ⅲ | φ3020*3300*12025 | (17850) | I-multi-layer winding | 0.100 | 0.03 | 30 | Jotun |

| HTC50 | 10.0 | 2.350 | <2.35 | 2.512 | -40 | Ⅲ | φ3020*3300*12025 | 21500 | I-multi-layer winding | ||||

| HT(Q)60/10 | 60.0 | 1.000 | <1.0 | 1.017 | -196 | Ⅱ | φ3020*3300*14025 | (20260) | I-multi-layer winding | 0.095 | 0.05 | 30 | Jotun |

| HT(Q)60/16 | 60.0 | 1.600 | <1.6 | 1.621 | -196 | Ⅲ | φ3020*3300*14025 | (31500) | I-multi-layer winding | 0.095 | 0.05 | 30 | Jotun |

| HT(Q)100/10 | 100.0 | 1.000 | <1.0 | 1.120 | -196 | Ⅲ | φ3320*3600*19500 | (35300) | I-multi-layer winding | 0.070 | 0.05 | 30 | Jotun |

| HT(Q)100/16 | 100.0 | 1.600 | <1.6 | 1.708 | -196 | Ⅲ | φ3320*3600*19500 | (40065) | I-multi-layer winding | 0.070 | 0.05 | 30 | Jotun |

| HT(Q)150/10 | 150.0 | 1.000 | <1.0 | 1.044 | -196 | Ⅲ | φ3820*22500 | 43200 | I-multi-layer winding | 0.055 | 0.05 | 30 | Jotun |

| HT(Q)150/16 | 150.0 | 1.600 | <1.6 | 1.629 | -196 | Ⅲ | φ3820*22500 | 50200 | I-multi-layer winding | 0.055 | 0.05 | 30 | Jotun |

Phawula:

1. Iiparamitha ezingentla zenzelwe ukuhlangabezana neeparitha ze-oxygen, i-nitrogen kunye ne-argon ngexesha elifanayo;

2. I-medium ingaba nayiphi na i-gas e-liquefied, kwaye i-parameters inokungahambelani namaxabiso etafile;

3. Umthamo / imilinganiselo ingaba nayiphi na ixabiso kwaye inokwenziwa ngokwezifiso;

4. Q imele ukomelezwa koxinzelelo, i-C ibhekisa kwitanki yokugcina i-carbon dioxide engamanzi;

5. Iiparamitha zamva nje zinokufumaneka kwinkampani yethu ngenxa yohlaziyo lwemveliso.